BGP Ma 131 Well 3D

BGP Sets New Acquisition Record in China with INOVA's 63,000 Channel G3i® System

In many regions of the world, the majority of geophysical service providers continue to use cable-based acquisition technologies for conducting the simplest 2D to the largest, most complex 3D surveys. Crews have equipped themselves with the most advanced cable-based systems on the market to take advantage of their unmatched reliability and accuracy in providing real-time data acquisition. As the seismic industry demands higher quality data at lower operational costs, acquiring high-density sampling with High Productivity Vibroseis (HPVS) is becoming more favorable. However, these projects introduce extreme challenges in managing equipment, personnel, logistics, and achieving desired productivity levels.

| Segment | |

|---|---|

| Region | |

| Technologies | |

| Related Products | G3i® NXT |

BGP has been exploring the Xinjiang Province of northwestern China for several years. The 150,000 sq. km (58,000 sq. mile) area is hydrocarbon rich and is the fourth largest onshore production area in China with an estimated 8.7 billion tons (63.7 billion barrels) of oil reserves. In 2013, the Xinjiang Oilfield Company, a subsidiary of PetroChina Company Limited and China National Petroleum Corporation (CNPC), awarded BGP a 3D project to explore 388 sq. km (150 sq. mi) of the Junggar Basin located in northern Xinjiang. BGP's client wanted to image targets down to approximately 4 km (2.5 mi) in depth to locate reservoirs and distinguish fault displacements. Seismic data from a prior 2D acquisition survey in this area was insufficient and the need for high fold, high resolution data became more apparent. Coupled with stringent design requirements and a tight schedule, BGP decided to perform this survey using more than 63,000 channels with a 52,000 live channel patch and Distance Separated Simultaneous Slip-sweep (DS4) operations. Widely accepted in the seismic industry, HPVS operations leverage multiple vibrators and sophisticated sweep techniques to obtain greater productivity than traditional source methodologies. Therefore, BGP needed a high-capacity acquisition system to support large-channel counts, continuous recording, and source-driven operations. In their 60 years of service, this project was BGP's first attempt to acquire seismic data using channel counts of this magnitude. Consequentially, it would become one of their most challenging projects as well, requiring extreme equipment management and logistical coordination for their super-crew.

BGP has been exploring the Xinjiang Province of northwestern China for several years. The 150,000 sq. km (58,000 sq. mile) area is hydrocarbon rich and is the fourth largest onshore production area in China with an estimated 8.7 billion tons (63.7 billion barrels) of oil reserves. In 2013, the Xinjiang Oilfield Company, a subsidiary of PetroChina Company Limited and China National Petroleum Corporation (CNPC), awarded BGP a 3D project to explore 388 sq. km (150 sq. mi) of the Junggar Basin located in northern Xinjiang. BGP's client wanted to image targets down to approximately 4 km (2.5 mi) in depth to locate reservoirs and distinguish fault displacements. Seismic data from a prior 2D acquisition survey in this area was insufficient and the need for high fold, high resolution data became more apparent. Coupled with stringent design requirements and a tight schedule, BGP decided to perform this survey using more than 63,000 channels with a 52,000 live channel patch and Distance Separated Simultaneous Slip-sweep (DS4) operations. Widely accepted in the seismic industry, HPVS operations leverage multiple vibrators and sophisticated sweep techniques to obtain greater productivity than traditional source methodologies. Therefore, BGP needed a high-capacity acquisition system to support large-channel counts, continuous recording, and source-driven operations. In their 60 years of service, this project was BGP's first attempt to acquire seismic data using channel counts of this magnitude. Consequentially, it would become one of their most challenging projects as well, requiring extreme equipment management and logistical coordination for their super-crew.

BGP selected INOVA's mega-channel G3i recording system since it supports over 100,000 channels with its advanced field electronics and state-of-the-art centrals. Within its first two years of release, crews have successfully deployed almost 200,000 channels of G3i in challenging terrains and under extreme temperature conditions around the world. BGP has operated the G3i system on numerous surveys and has become highly efficient in utilizing the system. Having gained valuable experience from completing smaller-scale projects, they had the utmost confidence in their abilities and G3i's proven field performance. As an integral part of INOVA's Clarity Broadband Solution™, the G3i cable-based system has always demonstrated ruggedness, reliability, and flexibility. Constructed of aircraft grade aluminum, its enclosures protect the electronics from damage during constant field transport and deployment handling—an attribute that is unique only to INOVA's system. Furthermore, the system's box-cable-box architecture, low power consumption, and intuitive software tools allow G3i to be the ideal cable-based solution for seismic super-crews.

.JPG)

BGP's ongoing partnership with INOVA enables access to the latest seismic technologies and exceptional customer support. Both companies understood the importance of this project and the challenges that lay ahead. And so in preparing for this survey, BGP purchased high performance central computers and several thousand additional G3i channels from INOVA to supplement their existing inventory. INOVA would also supply field service teams onsite to offer technical support if needed and ensure the G3i system operated without interruptions. Once the survey design was finalized, properly trained personnel became available, and adequate quantities of equipment were on hand, BGP mobilized its seismic crew #278 to begin operations in early October.

The oil field's landscape is composed mostly of desert gravel plains surrounded by small hills and gullies. The vast open land provided the crew with great latitudes of freedom for conducting High Productivity Vibroseis operations without obstructions from natural or cultural structures. To put its size in perspective, the project area of 388 sq. km is larger than some North American cities. This high-density, wide azimuth survey required more than 63,000 G3i channels, 15,000 receiver line cables, 60,000 analog geophone strings, 20 vibrators, and numerous support vehicles. BGP’s seismic crew deployed the equipment and completed sweep tests within three weeks. Even as temperatures crept down to -10 °C (14 °F), the determined crew continued to operate efficiently in the cold weather. They laid out nearly 3,300 km (2,100 mi) of copper receiver line cables and if one were to connect them together, it would create a communications pipeline from Calgary, Canada to Houston, Texas.

The super-patch of 52,000 live channels encompassed approximately 192 sq. km (75 sq. mi). Its design parameters included 39 receiver lines spaced 150 meters apart with 25-meter receiver intervals. Each geophone array of 10 analog phones had a 9 m x 9 m octagonal arrangement. The G3i system would record seismic data continuously at two-millisecond sample intervals. With the fast pace of shooting, the equipment would record almost 500 million traces per day. To meet the extreme data management challenge, BGP used INOVA's new PCI Express-based Seismic Processing Module (SPM) which is designed to handle data for up to 100,000 channels. A secondary computer, Quality Control Module (QCM), was also set up in the recording truck to perform real-time data QC and transfer data to removable hard drive modules. When faced with an unprecedented magnitude of incoming data from the field stations, the QCM can easily help crews maintain high levels of productivity.

Source operations took place 24 hours a day with twenty vibrators performing DS4 operations. The crew operated multiple vibe clusters, separated at distances of 14 km (8.7 mi), with dynamic fleet grouping to obtain higher productivity levels than conventional sweep techniques. The communications hardware and messaging protocols implemented within INOVA's products are essential for large-scale DS4 operations. BGP equipped each vibrator with INOVA's Vib Pro™ source controller and Connex™ Vib system. Vib Pro enabled the operator to have better force control, reduce harmonic distortions, and carry out source-driven acquisition. The Vib Pro encoder/decoder units allowed the crew to maintain efficient operations even with separation distances of up to 14 km (8.7 mi). BGP required a single radio frequency to establish proper communications for source control. The user-friendly Connex Vib system provided navigation and positioning of vibrators. This standalone system accurately recorded GPS coordinates, sweep start times, post sweep (PSS) attributes, and VSS ground force measurements. Source parameters included sweep times of 16 seconds and slip times between 9 and 11 seconds with a broadband frequency range of 3 Hz to 90 Hz. Source generation regularly exceeded 10,000 vibration points per day, totaling 290,772 source points while maintaining a PSS return rate of over 99%. In order to keep pace with the aggressive shooting schedule, the well-trained crew was rolling 5,000 to 6,000 channels per day. BGP was able to execute this immense acquisition operation with a combination of 675 personnel and INOVA’s advanced seismic technology.

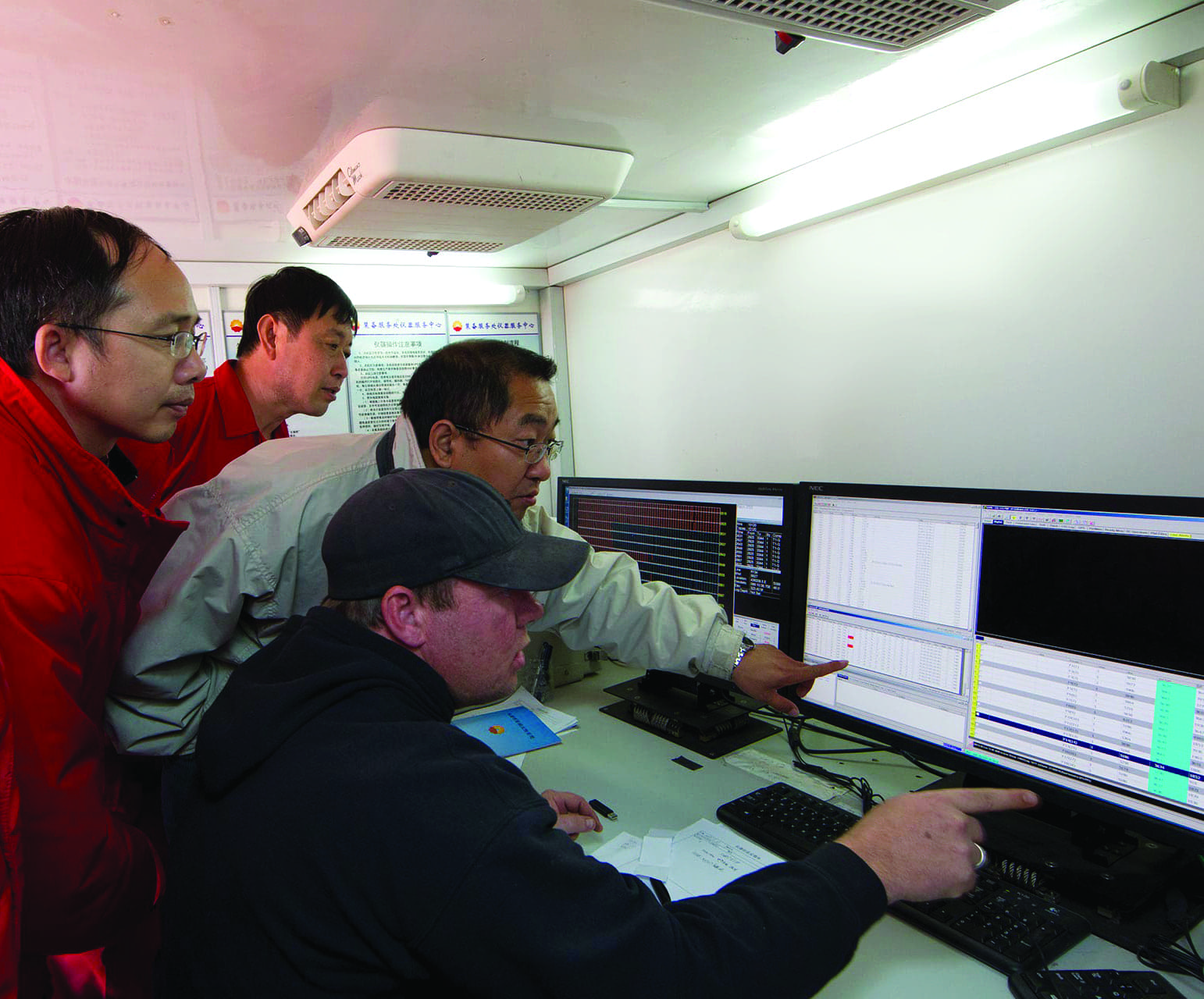

Representatives from several international E&P companies were invited to witness first-hand G3i’s performance and reliability in recording high-quality data. The visitors were interested in observing how BGP maximized production levels on such a massive project and were excited to see G3i's cutting-edge seismic acquisition technology in action. Inside the small recording truck, BGP geophysicists and other observers monitored real-time data during source operations using G3i's sophisticated software tools. The SPM central separated and correlated the two active patches within the super-patch during DS4 while handling multiple overlapping shots without computing delays. The system captured an average of six terabytes of data a day, which the operators off-loaded to removable hard drive modules for processing. As expected, INOVA's G3i system functioned according to its specifications and presented no issues in recording data throughout the spread.

This 3D survey was the largest channel count project in China and the third largest in the world to date. The attendees from the E&P companies, BGP management, and Xinjiang Oilfield Company were highly impressed with G3i's recording capabilities, and the crew's efficiency in quickly deploying equipment and conducting HPVS operations. BGP successfully completed the survey within six weeks and its results exceeded their own expectations in terms of crew management and equipment utilization. The Xinjiang Oilfield Company was so pleased with the project’s data quality and its high operational productivity that they scheduled another large-scale seismic survey of similar size in the Junggar Basin for February 2014. Furthermore, the visiting E&P personnel stated they were extremely satisfied in the abilities of BGP and the performance of INOVA's G3i system. BGP's advanced technology portfolio, their acquisition expertise in challenging environments, and their unwavering commitment to their customers sets them apart as the premier service provider for large-channel count projects anywhere in the world.