Desert

Desert Operations

About two-thirds of the world’s daily oil production comes from mature fields, according to a report from IHS Cambridge Energy Research Associates, and Halliburton suggests that around 80% of these fields are located in the Middle East and North Africa.

Brownfield optimization is the primary driver behind high-density broadband seismic acquisition. High-resolution imaging of not only the reservoir, but also the various migration pathways throughout the entire field, is needed to understand where injected fluids and gas accumulate, and the impact field flooding has on the formation and subsequent production volumes.

Fortunately, desert environments are the perfect host for high-density surveys on account of their isolation, limited vegetation and nothing but sand as far as the eye can see. (And let’s not forget the heat.) It’s also been the birthplace for many of today’s high-productivity vibroseis methods that are shattering seismic acquisition records.

View ProductsWe believe our collaboration on this project with INOVA helped narrow the gap between productivity and image quality...

— Said Mahrooqi, Head of Operations at Petroleum Development of Oman (PDO)

Did you know

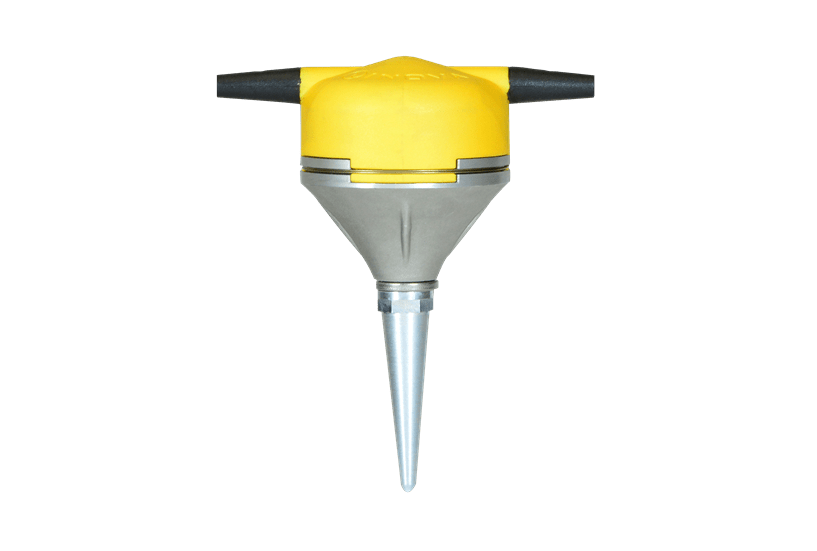

Adding Connex Vib and Vib Pro HD to an AHV-IV provides full visibility and QC over source operations when using the G3i NXT acquisition system.

More than 500 AHV-IV vibrators have been purchased by clients operating in desert environments

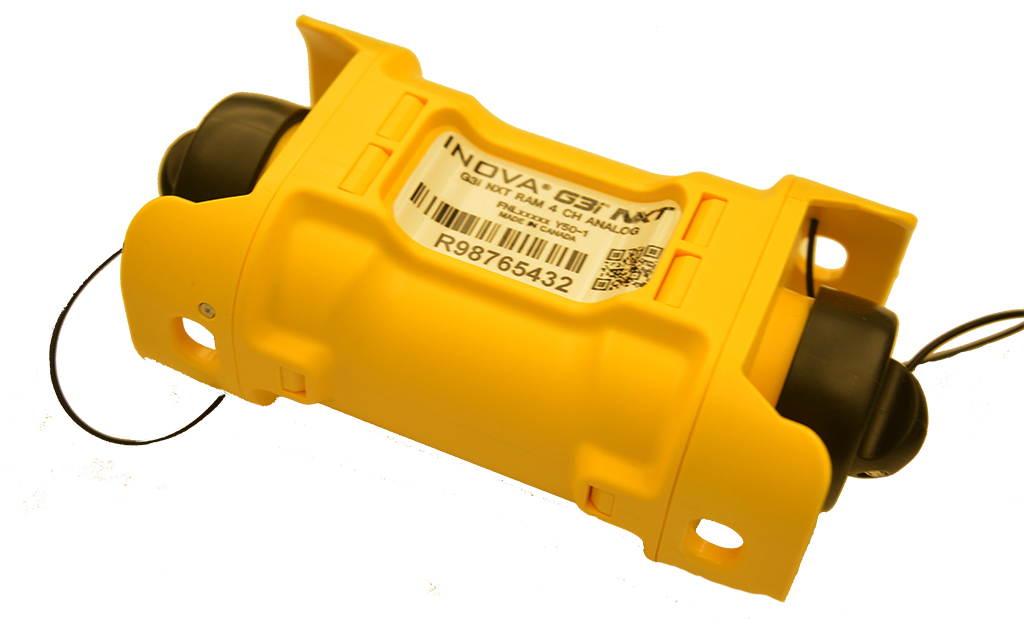

240,000 live channels and capacity for high-productivity vibroseis operations are just two of the many features in G3i NXT that supports cost-effective high-density surveys.

Overview Portfolio

Though challenging on crews and equipment, high channel count survey demand has pushed the envelope on technology and innovation. The size of the crews, the magnitude of the spread and the huge data volume is unmatched anywhere else in the world. Despite the enormity of these surveys, if you are doing any size acquisition in the desert, you are likely in need of equipment able to tolerate the extreme heat, sand, and dust storms common in this environment.Here are a few helpful tips:

Usable Force

Loosely consolidated materials such as sand can weaken signal penetration which tends to be compensated by adding more vibrators to a fleet. If you utilize the combination of an AHV-IV and a Vib Pro HD controller, you can generate more usable energy thereby reducing the number of vibs required per source point. You can also utilize an 80,000 lb vibrator to support better coupling.

Redundancy and Troubleshooting

Troubleshooting and battery management in the desert should be kept to a minimum so as to reduce downtime, particularly during high-productivity, 24-hour vibroseis operations. The G3i NXT has transmission pairs within the cable for redundancy to reroute data in the event of a line break. Additionally, the LED indicators on the field equipment make it easy to locate and troubleshoot issues quickly.

Hybrid Operations

For high-density cable-based surveys that require in-fill between receiver lines, autonomous nodes could be a good option. However, most cable and nodal systems operate independently requiring master/slave recording, which increases the complexity of data management and conditioning. If you deploy a G3i NXT with Hawk or Quantum, you can reduce data collection complexities and provide a single SEG-Y or SEG-D dataset while managing the full spread from one console.

Rugged and Reliable

As dust storm size and frequency could increase with continued climate change, it becomes important for crews to protect ground electronics and later locate and/or retrieve them after a storm. The ruggedized G3i NXT system components made from aircraft grade aluminum (vs. plastic) tightly encloses the electronics and protects them from sand intrusion.

Featured Products

Sales + Rentals

.JPG)