Tesla Rocky Mountain

Tesla Rocky Mountain Autonomous Nodal Hawk® System from INOVA Conquers the Canadian Rockies

Tesla Exploration Ltd. was selected for the Willesden Green 3D/3C seismic acquisition project, a winter deployment covering 260 sq km (100 sq mi) near Rocky Mountain House in Alberta, Canada. The project area encompassed a working oil field production area and unpopulated terrain with rolling hills and patches of dense evergreen forest. Unpaved roads offered reasonable access, but Tesla crews also required snowmobiles in off-road areas for greater efficiency in deployment and acquisition QC.

| Segment | Land Seismic Acquisition |

|---|---|

| Region | Canadian Rockies |

| Technologies | Hawk Autonomous Nodal System |

| Related Products |

Subarctic Extremity

As autonomous nodes make their way into the mainstream of acquisition technologies, successful cableless acquisition projects span a wide variety of difficult terrains and environments. The benefits of cableless architecture are well recognized in overcoming a diversity of operational challenges. Seismic operations in the freezing Canadian winter environment represent an extreme challenge for equipment and personnel, even for traditional cable-based systems. Tesla Exploration Ltd. was selected for the Willesden Green 3D/3C seismic acquisition project, a winter deployment covering 260 sq km (100 sq mi) near Rocky Mountain House in Alberta, Canada. The project area encompassed a working oil field production area and unpopulated terrain with rolling hills and patches of dense evergreen forest. Unpaved roads offered reasonable access, but Tesla crews also required snowmobiles in off road areas for greater efficiency in deployment and acquisition QC.

Superior Flexibility

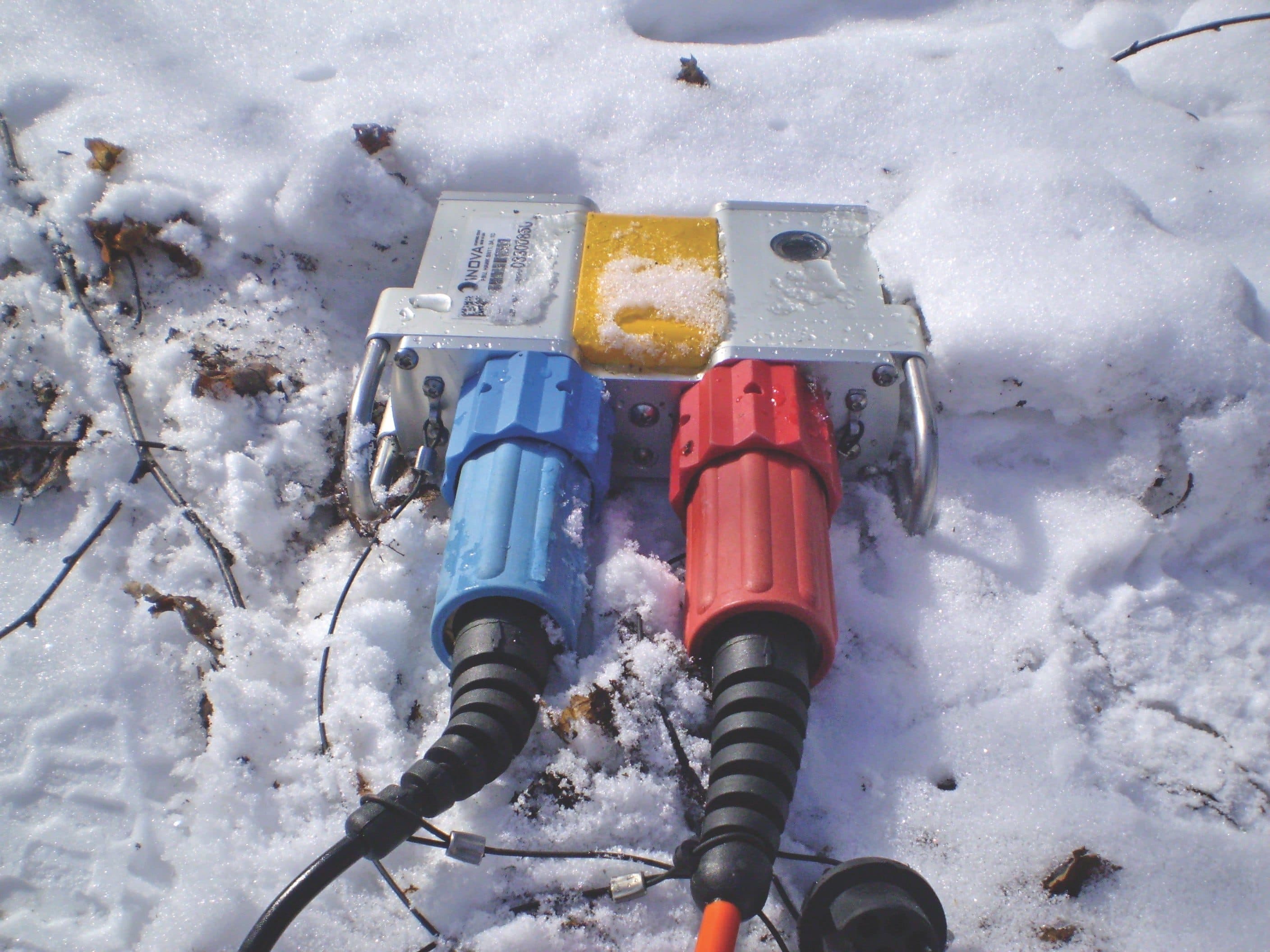

It was a big step to go cableless on a winter project in the Canadian Rockies. Tesla needed a system that could offer robust recording reliability in frigid temperatures, rugged durability in cold field handling, and optimal flexibility for crew operations. A successful history of utilizing INOVA's Hawk system on a number of earlier acquisition projects gave Tesla confidence to recommend the Hawk system to their client. The project required 10,000 Hawk field stations, 10,000 three-component analog geophones, and 12,000 batteries for a very dense, high fold, wide azimuth state-of -the-art survey with 100% dynamite source production. A helicopter for field equipment transport streamlined the crew’s efficiency in the layout and pickup process. Customized satchels with a full station’s gear made deployment easier for the crew. A helicopter equipped with the Connex™ Field Harvest Tool offered fly-by routine spread QC during acquisition to alleviate concerns of data collection reliability and quality. The crew also quickly performed targeted QC on snowmobiles so they could achieve maximum productivity.

Sustained Operability

For several days, Tesla encountered 2-6 inches of snow and temperatures dipped to -21°C (-6°F). Even fully buried in snow, Hawk units maintained their GPS lock and continuously recorded high-quality data. The QC crew reported no issues with Wi-Fi technology performance in the cold air, and the efficient operation quickly dispelled concerns about battery runtime in this challenging environment. Despite these cold temperatures, batteries performed according to specifications. As stations cycled from the field, custom-configured trailers enabled quicker battery warm-up prior to recharging. Hawk data download time is among the fastest in the industry—5X faster to download shot records as compared to downloading all the continuous data. Despite the harsh conditions, source operations averaged 450 shots per day with a 708 single day shot maximum, while maintaining a trace yield greater than 99% for the project.

Superb Durability

This project demonstrated Hawk’s performance, capability, and reliability in recording high-quality data in Canada's harsh winter conditions. Hawk’s aircraft grade aluminum enclosure has endured the cold temperatures, and has proven its rugged superiority in withstanding constant field transport and deployment handling. Tesla was successful in leveraging Hawk’s strengths and added customized equipment to gain operational efficiency and meet the challenges of the winter project. Tesla completed this project in just under a month, delivering high quality data and once again proving Hawk’s durability and adaptability. The Tesla crew and Hawk equipment will return to the project site and conduct a much larger survey later this year.